-

SMART MATERIALSBreathable and waterproof only when needed. For Shoes, Clothing and in Technical field.

SMART MATERIALSBreathable and waterproof only when needed. For Shoes, Clothing and in Technical field.

The innovation for shoes and textiles

It is the combination of specific properties which makes IQTEX materials so unique.

Patented technologies

Every company is trying to increase its share of the market. This is a lot easier if the company is able to offer products which have unique properties that competitors are not able to deliver. Innovative ideas protected by patents ensure exactly this advance permanently. Benefit from numerous technologies that IQTEX has patented in recent years and get the edge over your competitors.

Built PTFE free

and recyclable

Almost all current membrane systems use halogenated carbons like PolyTetraFluoroethylene (PTFE), which releases significant amounts of very toxic substances in its production or during disposal.

The IQTEX laminate consists of polyester and sodium polyacrylates, and within these, we only use carbon, hydrogen, oxygen and sodium. Thus, the laminate can easily be recycled or incinerated in an environmentally friendly way.

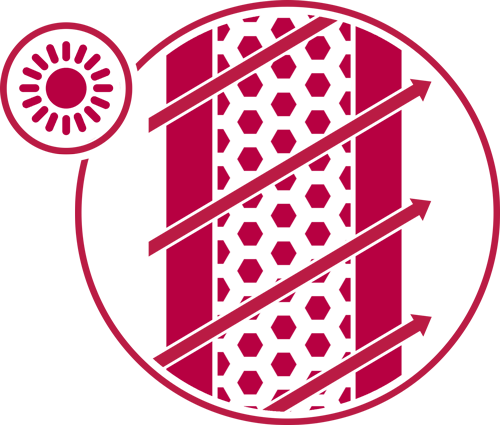

Ultra high

breathability

Almost all of the functional waterproof membrane systems are also windproof. Because of that these membrane systems sabotage perspiration, the natural function of the skin to regulate body temperature. The humidity below the clothes heats one up quickly. The ultra high breathability of the IQTEX laminate removes a lot more water vapour and the well-being remains significantly longer even at intense activity or higher ambient temperatures.

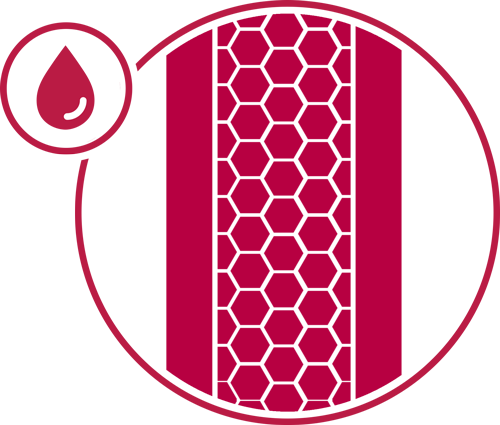

Reliable waterproof

The IQTEX laminate has an ultra high air permeability, yet it is also waterproof. This behaviour is made possible by the superabsorbent polymers in the laminate, which swell in contact with water thereby sealing the cavities within. These cavities allow in dry conditions the ultra high breathability.

Science around us

Video Clip

Source: BASF

Material in dry conditions

In dry conditions a lot of air can find its way through the superabsorbent polymer layer as there is plenty of space between the particles of the superabsorbent polymer which is limited on both sides by two fleece layers. So on one hand dry air is able to get from the outside to the body much easier and on the other hand warm and humid air can be transported much faster away from the body. The natural regulation of body temperature is supported perfectly.

Material in wet conditions

If water finds ist way through the outer fleece, the particles of the superabsorbent polymer will swell. They are much bigger now than in the dry state. As the room between the two fleeces is limited by adhesives, the layer with the superabsorbent polymers cannot expand. The IQTEX laminate remains its dimensions. Therefore all particles of the superabsorbent polymers press against each other so tightly that the material becomes quickly waterproof. When the material is dry again the ultra high air permeability will be restored completely.

Possible applications

Basically IQTEX laminates can be used in every field as textiles or functional membranes. The focus of IQTEX activities lies right now on the shoe production.

Application as insole material

Feet have more than 250.000 sweat glands for perspiration. Therefore the demand for ventilation is complex and couldn’t be solved yet in a satisfying way. Due to the ultra high air permeability in combination with the waterproofness IQTEX laminates become the perfect material for insole solutions. The material is not a mere idea. It is produced and sold by a German company, Freudenberg (www.freudenberg.com) and it is called „Airliner“. It has been used in shoes millionfold.

Application as upper material

IQTEX laminates can be used directly for ventilation purposes as upper. This material is also produced by Freudenberg. A classic functional membrane has one state which always stays pretty much the same. It does not matter whether it is cold or warm – wet or dry. In contrast to these classic membrane systems IQTEX laminates adapt themselves to the Environment without steps.

More information: https://www.youtube.com/watch?v=OMHmolzJQmo

Copyright by Freudenberg SE: https://www.freudenberg-pm.com/Storys/Respiro

Application in the technical field

IQTEX laminates are used in VAYU TEC protection vents. On this field they compete with vents with classic ePTFE membranes.

Higher water entry point

The quality of vents can be determined by regarding the pressure at which water is able to get into the element the first time. The higher this pressure is the higher the safety reserves are. Comparing a VAYU TEC protection vent with an ePTFE membrane system you will find that VAYU TEC is 6 times more safe. The Water entry point of the ePTFE membrane is at 1 bar while VAYU TEC is tight up to at least 6 bar.

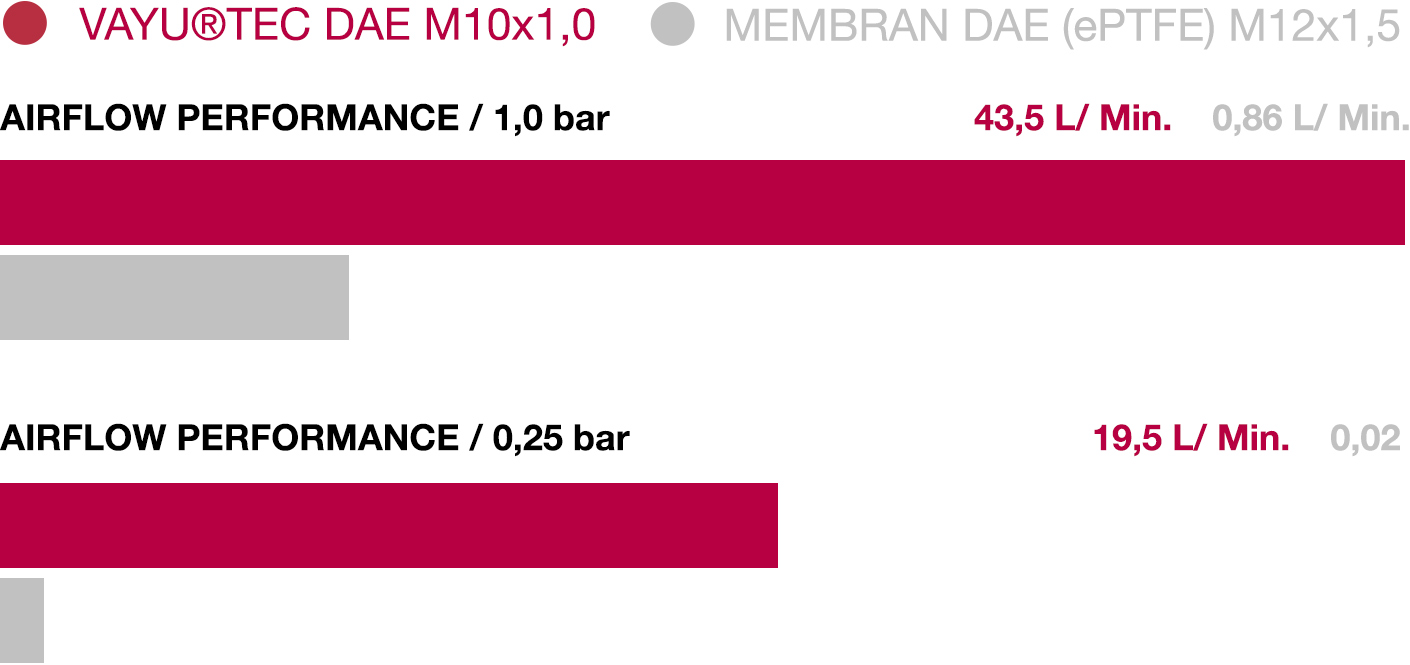

High performance

This comparison underlines the ultra high air permeability of IQTEX laminates: The air permeability at 1.0 bar pressure difference is about 50 times greater than those of ePTFE membranes. Regarding a pressure difference of about 0.25 bar the IQTEX laminate passes through 975 times more air than an ePTFE membrane.

Transferring that knowledge to the shoe industry it is immediately obvious that it does not matter at all how many times you perforate an outer sole for the IQTEX Airliner. The so called „breathability“ of a shoe with a conventional ePTFE membrane will always be worse – even if one would leave out the complete TPU or rubber sole and take the pure membrane alone.

Cost advantage

This means that if you have a pressure difference of 0.25 bar and you should need to change about 20 litres of air per minute in a ventilation process, then you will need 975 protection vents with ePTFE membrane. Or just one with IQTEX laminate! So VAYU TEC is less expensive which is another clear advantage. Besides the fact that 975 ePTFE protection vents may need a little more space to be installed than one single VAYU TEC protection vent.

Apart from that one single VAYU TEC vent is even smaller than one ePTFE protection vent.

Application in the automotive industry

For ventilation in the electronics sector, especially for ventilation of lithium-ion technology and solid state batteries.

Read more www.vayutec.com/homepage-en.html